Solenoid valves, timers, boilers, wall bushings, probes and vent panels.

Components and automatisms that complementarily play a basic and determining role in the final result of the filtration process and efficiency of the filtering medium

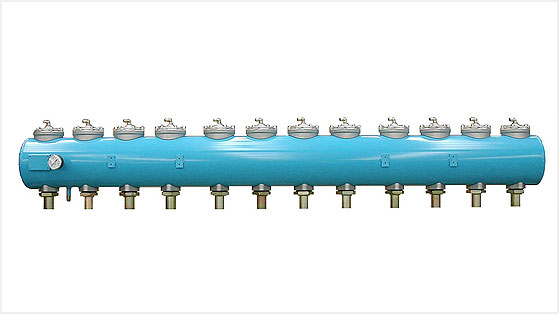

The Boilers

In the first scenario, the BOILERS are active tanks of pressurised clean air which, after each cleaning cycle, will collect the volume of air required for the next cycle.

The Timers

This air will be managed electronically through the TIMERS (electronic control system) which, by a remote control, will safely monitor the efficient distribution of clean air during the cleaning cycle, within the framework of action set by the different set points under which the whole system will work together.

The solenoid valve

This process is managed through a key and dynamic figure in the whole process, the solenoid valve, which controls with maximum efficiency the air circulation through the filter bag to achieve an optimal and reliable cleaning of the same, ultimately responsible for materialising and giving life to the whole cleaning process, safeguarding the load losses that the fabric supports for its correct operation.

Do you need further information about this product?